CANVASA

Klick auf den QR-Code und hole dir die Canvasa virtuell in deine Produktion

Innovative

Fülltechnologie

Die steigende Nachfrage nach Mikrofüllern made in Germany hat uns dazu bewegt die Canvasa ins Leben zu rufen. Als einer der Innovationsführer haben wir den weltweit kompaktesten Dosenfüller mit patentierter Gegendrucktechnik entwickelt.

Die Maschine hat den Footprint einer Standard-Europalette und kann aufgrund ihrer Mobilität immer und überall eingesetzt werden.

Die Canvasa ist eine kompakte, halbautomatische Dosenfüllmaschine. Die neu entwickelte und patentierte Gegendruck-Fülltechnik erlaubt es, sowohl karbonisierte als auch nicht karbonisierte (stille) Produkte besonders schonend und bei minimalem Sauerstoffeintrag zu füllen.

Mittels Zubehör wie Depalettiertisch, automatischem Rinser, Etikettierer, etc., kann die Canvasa zu einer kleinen, günstigen und vollautomatischen “Minilinie” erweitert werden.

Die Maschine kann alle gängigen Dosenformate wie Standard, Sleek oder Slim verarbeiten. Gerade für Start-ups oder Getränkehersteller, welche Dosen erstmal nur “ausprobieren” möchten ist die Canvasa das ideale Einstiegsmodell.

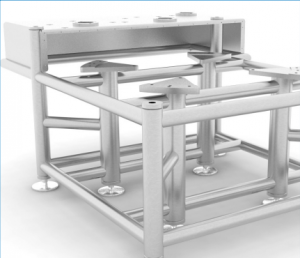

Durch seine offene Konstruktionsweise entsprechen wir dem Grundgedanken des Hygienic Design. Generell werden die Füllmaschinen von Leibinger so mechanisch wie möglich konstruiert und gebaut, sodass auch der empfohlene jährliche Wartungsservice werksintern von den eigenen Mechanikern durchgeführt werden kann.

Fragen Sie bei diesem Modell auch unsere interessanten Leasingmöglichkeiten an.

TYP

Dosenfüller

TECHNIK

Gegendruck

Füllventil

STELLENANZAHL

2

PRODUKTE

alle Getränke

LEISTUNG

360 – 1.200 D/h

O2 PICKUP

10-60 ppb

Füllventil

Handrinser

HDE Heizung

HDE

Rahmen

Verschließer

Panel

Weitere Eigenschaften

Bauweise

Durch die kompakte Bauweise passt die Canvasa auf eine gewöhnliche Europalette und kann mobil eingesetzt werden.

CIP

Unsere Abfüllmaschine ist CIP fähig. Ein geschlossener Kreislauf mit Dummy Dosen sowie die verwendeten Dichtungsmaterialien sorgen dafür, dass die Maschine sowohl mit Säure- als auch mit Laugenkonzentrationen gereinigt werden kann.

Druckerhöhungspumpe

Die Druckerhöhungspumpe ist dafür zuständig den Wasserdruck zu erhöhen und um mögliche Fluktuation des Hauswasserdrucks zu kompensieren. Sie sorgt für einen permanent konstant gehaltenen Wasserdruck für die HDE und dieser lässt sich über das Panel einstellen.

Key Facts

Die HDE Heizung dient der kontinuierlichen Versorgung mit mindestens 80°C Grad heißem Wasser. Somit ist das HDE Wasser keimfrei.

Der speziell entwickelte Verschließer sorgt für die ordnungsgemäße Umbördelung der Dosendeckel. Jede Maschine wird vor dem Verlassen des Werkes auf einen normgerechten Verschluss geprüft.

Durch das Leibinger Grundgestell haben wir möglichst viele horizontale Flächen abgeschafft, sodass überschüssiges Wasser oder Produkt jederzeit abfließen kann. Damit entsprechen wir dem Gedanken des Hygienic Design.

Durch die kompakte Bauweise passt die Canvasa auf eine gewöhnliche Europalette und kann mobil eingesetzt werden.

Unsere Abfüllmaschine ist CIP fähig. Ein geschlossener Kreislauf mit Dummy Dosen sowie die verwendeten Dichtungsmaterialien sorgen dafür, dass die Maschine sowohl mit Säure- als auch mit Laugenkonzentrationen gereinigt werden kann.

Unsere Siemens-basierte Steuerung ist ähnlich einem Smartphone intuitiv bedienbar. Über den HOME-Button kann die Maschine bedient werden.

Die Druckerhöhungspumpe ist dafür zuständig den Wasserdruck zu erhöhen und um mögliche Fluktuation des Hauswasserdrucks zu kompensieren. Sie sorgt für einen permanent konstant gehaltenen Wasserdruck für die HDE und dieser lässt sich über das Panel einstellen.

RINSEN

FÜLLEN

VERSCHLIEßEN

Zusatzoptionen

Automatischer Rinser

Der automatische Rinser spült die Dosen und befreit sie von jeglichen Rückständen. Damit werden die Behälter für die Abfüllung vorbereitet.

Halbautomatischer Depalettiertisch

Der Depalettiertisch erlaubt das Halbautomatischer depalettieren von halben Dosenpalletten. Diese werden mittels eines Hubwagens oder mit einem Gabelstapler auf die entsprechende Höhe gebracht und mit einem Abschieber auf den Drehtisch befördert. Der Drehtisch fördert die Dosen dann vollautomatisch weiter in den Rinser, welcher auch einzeln dazu bestellt werden kann.

Drehender Sammeltisch

Der Sammeltisch ist ein kleiner drehender Tisch, welcher die Dosen am Auslauf der Canvasa aufnimmt, sodass diese nicht permanent händisch abgenommen werden müssen. Er kann anstelle der Etikettiermaschine oder des Transportbandes eingesetzt werden.

Selbstklebeetikettierer (Fa. GERNEP) – Etikettendatumsdrucker

Von der Firma Gernep bieten wir einen kleinen Etikettierer an, welcher alle gängigen Dosenformate mit selbstklebenden Etiketten beklebt.

Dosendatumsdrucker

Zum Bedrucken des Dosenbodens mit Mindesthaltbarkeitsdatum oder Trackingnummer (Fa. Paul Leibinger GmbH & Co. KG). Nur in Kombination mit dem automatischen Rinser.

Druckererhöhungspumpe HDE

Die Druckerhöhungspumpe dient dazu den Druck zu erhöhen oder möglichen Druckschwankungen entgegen zu wirken.

Technische Details

Nennleistung

360 – 1.200 D/h (Standard, Sleek oder Slim Dosen)*

Steuerung

Siemens

Anschlusswerte

230 V / 50 Hz**

Verschließer

Leibinger

Verschließwerkzeug

Leibinger

Füllventilachse

Festo

Antriebe

Siemens / SEW

Hygienic Design

Eine Rundrohrkonstruktion als Ersatz für die klassische Tischplatte.

*produktspezifisch **länderspezifisch

Verschiedene Flaschen- & Dosenformate und Füllhöhen

Materialien

FüllrohreEdelstahl (1.4571 or 1.4404)

Lebensmittelechter Kunststoff (z.B. POM or PTFE)

Leitungen aus Edelstahl (1.4404)

Zuverlässigkeit

Personalzeiten reduzieren

Sicherheitseinhausung

Weitere Merkmale

Hygienic Design®

Ein Schritt in der Entwicklung des Leibinger Hygienic Design® Konzepts war die Eliminierung möglichst vieler horizontaler Flächen.

Das Ergebnis: eine Rundrohrkonstruktion als Ersatz für die klassische Tischplatte.

Downloads

Layouts

CANVASA anfragen

Wir freuen uns, Ihnen weiterzuhelfen! Nutzen Sie bitte das Kontaktformular für allgemeine Anliegen und das Anfrageformular, wenn Sie nähere Informationen zu unseren Abfüllmaschinen wünschen.

WELTWEIT GANZ NAH

Leibinger Remote Service

Mit dem Leibinger Remote Service können wir Ihnen aus der Ferne helfen, Ihre Maschinen selbst zu reparieren.